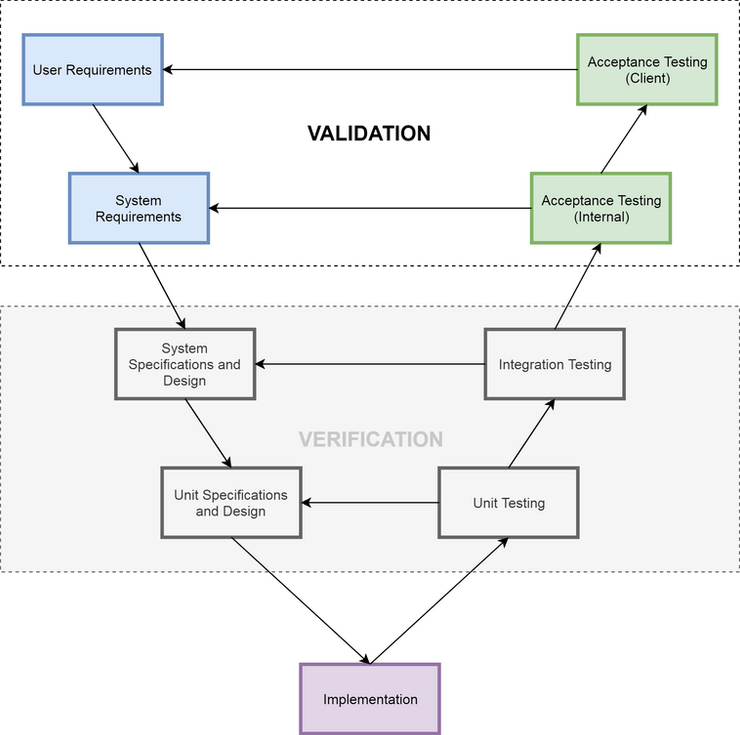

Verification & Validation

Verification & Validation go hand in hand to ensure the design and delivery of a great product.

A common characteristic of all these testing activities is that they can be automated to gain efficiency and repeatability, and thus to enable delivery of better products faster.

Validation

Validation tests the product’s specifications, as well as the finished product itself, against the client requirements. It ensures the product is designed to meet the client’s needs. It also acts as the feedback necessary to iterate product versions converging to a version which fully meets the internal and client requirements.

Acceptance Testing (Client)

Upon delivery of the product, the client validates that the product meets its requirements. This can range from plugging in a television and verifying that you can change the channel to very complex pre-approved validation testing at the client site.

Acceptance Testing (Internal)

To the best of its abilities, the designing entity validates that the product will meet the client’s requirements by putting itself in the client’s place.

Verification

Verification tests the product’s design against its specifications. It ensures that the design and every unit produced meet their specifications and that they can be delivered to its intended user.

Integration Testing

Integration testing consists in the verification of the whole system. It tests the integration of the software, the different electronic components and the mechanical enclosure and how they perform together against the system’s specifications.

These activities can be split into two modes of testing, design verification and production line verification:

-

Design Verification

- Typically performed by R&D engineers.

- Performed on 3 or more assembled systems every product revision

- The fully assembled system, with delivery software or firmware installed, is tested to verify that every one of its interfaces perform to the stated specifications of the product.

Example: Verifies that the product’s transmitter meets the industry standards for its class in all environments and usage modes.

-

Production Line Verification

- Typically performed by assemblers-testers or production technicians

- Performed on all assembled systems on the production line

- The production line integration test plan is typically a subset on the Product Design Verification’s one.

- The integration test typically includes the installation of the delivery software or firmware

- Each of the product’s interfaces are tested to ensure that the system parts are properly assembled and the software successfully deployed.

Example: Verifies that the product’s transmitter is functional, cables and connectors are properly assembled and that it transmits at nominal power.

Unit Testing

Unit testing is more commonly thought of as a method of software testing, where a module or function is tested using many different input types and values to verify its outputs.

The same applies to hardware testing. For example, a power-supply-module unit test would consist in feeding different input signals iterating on voltage, ripple and stability parameters, all while verifying the power supply outputs at different points. The power supply could fail and fall short of its specifications due to a routing issue (i.e. trace too long), a missing or mis-sized component (i.e. capacitor) or other design issues.

These activities can be split into two modes of testing, design verification and production line verification:

-

Design Verification

- Typically performed by R&D engineers.

- Performed on 3 or more electronic cards every hardware revision.

- Each of the interfaces and sub-systems of the individual electronic cards composing the system are tested to verify that the design implementation meets the chosen components specifications.

Example: Verification of rise times, frequency and jitter on every data, address and clock pins of a memory chip, ensuring that the memory circuit design performs to specifications.

-

Production Line Verification

- Typically performed by assemblers-testers or production technicians

- Performed on all assembled electronic cards on the production line

- The production line test plan is typically a subset on the Electronic Design Verification’s one.

- Each of the interfaces and sub-systems of the electronic cards are verified to ensure that all components are properly assembled.

Example: Verification of memory functionality by the execution of writes and reads, ensuring that the memory is correctly assembled on the electronic card.